Die-cutting has a long history and comes in many forms. Two of the most prominent are kiss-cutting and through-cutting.

Each approach results in different production processes and maintenance concerns. Kiss-cutting produces a large number of labels quickly. Through-cutting produces individual labels at a slower rate. They also interact differently with the facestock, adhesive and liner. Both methods are used in the converting industry and many others.

Learn more about each type and how they interact with different liners.

What Is the Difference Between Kiss-Cutting and Through-Cutting?

All cutting techniques involve the die blade passing through the label’s construction. What separates the cutting types is how far they go.

We have the skills and expertise to provide you with die cutting solutions you can depend on. Ready to experience the Best Cutting Die difference? Contact our knowledgeable team today by completing our online form or calling us at (847) 654-9520.

Kiss-cutting passes through the label’s facestock and adhesive layer but stops short of the liner. The liner then acts as a carrier for the labels. This approach results in rolls or sheets of labels. Kiss-cut labels are easy to remove and place where needed. Kiss-cutting labels is faster, and the rolls produced are generally compatible with automatic label applicators, which need an intact liner to do their work.

Through-cutting cuts through all three layers — the facestock, adhesive and liner. A hardened anvil roll sits behind the label to absorb the force of the cut. Because of that extra force, through-cut labels can be made of paper, vinyl, cardboard or other materials. Through-cutting tends to be slower, though, so it’s often used to create promotional items with unique shapes.

Kiss-Cut vs. Through-Cut: A Head-to-Head Comparison

Each cutting method has its uses and limitations. Deciding between them is a matter of understanding these traits and identifying which best serves your needs.

Four of the most prominent factors to consider are:

| Kiss-Cut | Through-Cut | |

| Final production format | Produced on a continuous roll | Come individually or in stacked sets |

| Application method | Rolls are often fed into automatic label applicators | Labels are usually applied by hand |

| Production speed | Faster, cuts through fewer layers and softer material | Slower, cuts through more layers and more robust material |

| Tooling stress and wear | Puts less pressure on the blade for less frequent replacement | Puts more pressure on the blade for more frequent replacement |

Optimizing Your Kiss-Cut Settings by Liner Type

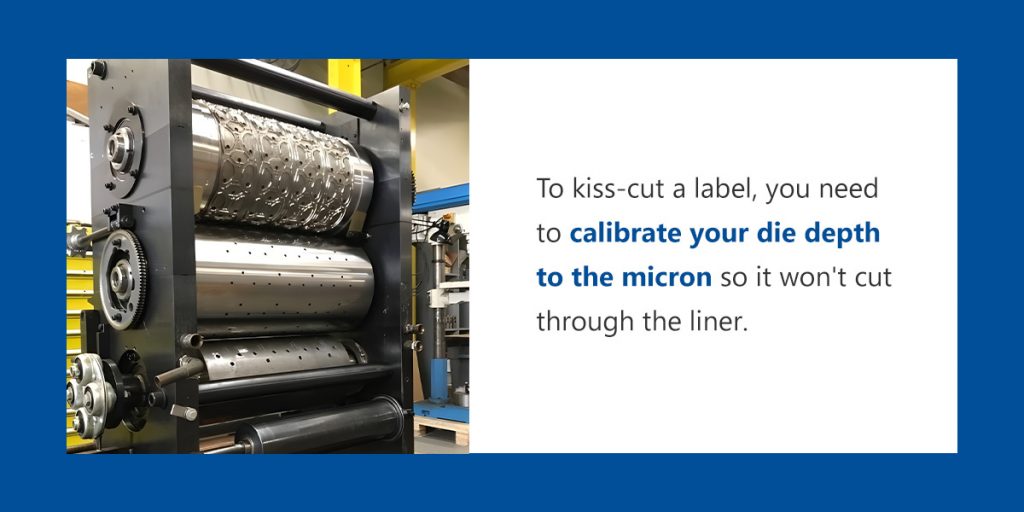

To kiss-cut a label, you need to calibrate your die depth to the micron so it won’t cut through the liner. Different liner types require different die depths, though. They also require different pressures and die angles. Kiss-cut pressure tends to be lower than through-cut pressure to preserve the liner. Without the proper settings, the die will not produce functional labels or liners.

Here’s how you can adapt your kiss-cut settings to the three major liner types:

- Kraft liners: Kraft paper is a fibrous liner that provides a cushion during the cutting process. If the cut goes too deep, though, the liner may experience adhesive ooze. This can damage the die and other components over time. To avoid this fate, use a sharper die angle and higher pressure. These settings will cleanly sever the facestock from the liner without cutting through it. Flexible rotary dies are a great option here.

- Polyester (PET) liners: These liners are the thinnest of the three. They are quite strong and stable, though. This balance makes them ideal for high-speed converting but increases the risk of liner strike. The best way to minimize this risk is to maintain a precise die pressure and a micron-specific blade height.

- Glassine liners: Glassine is a supercalendered (SC) paper with a smooth, glossy surface. It is denser than kraft paper and more forgiving than PET liners. Your blade settings can be a bit looser as a result. The real challenge of glassine liners is their sensitivity to humidity. The liner can become brittle, which alters cut depth. Precise environmental controls minimize this risk and lead to more consistent cuts.

Optimizing Your Through-Cut Settings by Liner Type

Through-cutting a label requires different settings, as the die blade must cut completely through the liner. The goal is not to preserve the liner but to create a clean liner edge that is free of dust, burrs and frayed fibers. These settings will also change based on the liner type.

Here’s how to adjust your through-cut settings to each of the major types:

- Kraft liners: Because of kraft paper’s fibrous texture, it can only be cut cleanly by a strong die at a high-pressure setting. Otherwise, the label will have a frayed edge. These settings lead to a high level of die wear, so it’s important to inspect the die regularly and replace it when necessary. Wear lines will also begin to form on the anvil’s surface. These liners increase die wear even further, so you will need to replace it more often.

- Polyester (PET) liners: To cut through stiff PET liners, you’ll need a very sharp and wear-resistant die. Solid rotary dies are often the best option here. Their durability allows them to handle long-run through-cutting, even with filmic materials like PET liners. They can cut cleanly through the liner without producing plastic “angel hair” or dust.

- Glassine liners: Should glassine become brittle, it can experience chipping. Microcracks may also form along the cut edge if your die becomes even slightly dull. You can identify these issues by looking for a starburst pattern along the cut edge. Keeping your blade sharp and your anvil strong can minimize this issue. Liner parts must also be cleanly ejected from the web so they don’t impact the cut.

Troubleshooting Common Kiss-Cutting and Through-Cutting Defects

Cutting processes are susceptible to various defects. These defects may occur as a result of faulty blade settings or normal wear and tear. Either way, they can cause machine downtime and slow converting processes. Luckily, many of the most common defects have relatively straightforward fixes.

Here are three of the most common defects and how to fix them:

- Matrix breaks: Kiss-cutting processes have to separate waste materials, also called the matrix, from the liner. If the blade fails to cut through the facestock fully, though, the matrix can tear and stop the presses. Dull or damaged blades often cause matrix breaks. Your first step, then, should be to inspect the blade and sharpen or replace it. If the blade is functional, the problem may be the blade pressure. Try recalibrating it to see if it changes the quality of the cut.

- Adhesive ooze: When blade pressure is too high, it can squeeze the adhesive from between the facestock and liner. The adhesive then builds up on the die and other components. Over time, this can lead to malfunctions and excess wear. Both kiss-cutting and through-cutting can experience this issue. The best way to resolve it is to reduce the die pressure incrementally until you stop experiencing adhesive ooze. In some cases, though, you may need to invest in a higher-viscosity adhesive or a non-stick coating for the die.

- Edge rollover: If the edge of your labels begins to curl or fold, you’re experiencing edge rollover. This is a sign that your die is becoming too dull to cut cleanly. It could also indicate that the gap between the die and the anvil roll is too large. Both kiss-cutting and through-cutting experience edge rollover. Typically, you can resolve the problem by replacing your die blade or investing in die resharpening services.

Partner With Best Cutting Die for Dies and Repairs

Best Cutting Die has been the leading die casting company in the U.S. since 1966. We provide built-to-order dies to converting companies around the country, and we can help you arrange your cutting floor and processes for optimal efficiency. Our resharpen, repair and retool services keep your dies functional and efficient, too. Whatever your needs, Best Cutting Die is here to help.

To learn more about our custom design services, request a quote or talk with a technical consultant at (847) 649-6549.