Die Maintenance: How to Maintain Your Dies

Cutting dies are used in various industries to make everything from clothes to custom packaging. Dies need to cut precise forms from various materials to make these products. Achieving this precision requires dies to remain in top condition at all times, which is why it is crucial that you have an effective die maintenance schedule as part of your tool room management strategy.

Die maintenance ensures die-cutting equipment continues to function correctly, meets original equipment manufacturer (OEM) standards and prolongs its life span. It can also help prevent costly delays in the case of equipment failure and improve the safety of production lines.

Tool Room Management and How It Impacts Die Quality

Tool room management focuses on the tools and equipment used in production lines. It is a strategy that ensures sufficient spare parts and tools to perform maintenance and repairs quickly and adequately on vital production equipment. Tool room management also aids technicians and operations in finding the required parts and tools easily. The strategy helps reduce downtime, improves the longevity of equipment and helps keep production operations organized.

Two essential aspects of tool room management include die management and die maintenance.

What Is Die Maintenance?

Over time, dies experience natural wear and tear that can affect their performance. Die maintenance is the upkeep of dies and related equipment to ensure they function correctly. It includes inspecting, cleaning, lubricating, sharpening and replacing worn or damaged parts.

Proper die maintenance ensures dies continue creating high-quality products. Die maintenance is an essential part of die and tool room management. Both of these strategies play a key role in maintaining die-cutting equipment and the continuity of your production line.

What Is Die Management?

Die management is focused on monitoring and tracking dies and die-cutting machines. It includes a numbered inventory of dies, a strict check-in and checkout process, and a system to track and locate a die at any time. The check-in process should include a guide on how dies should be returned and what condition they should be in. Die management can help monitor the die’s condition and guide die maintenance schedules.

How Do You Maintain a Die?

There are various aspects to die maintenance. The first step is to create a schedule that allows time for your team to perform regular maintenance without interrupting your workflow. The schedule can be based on the number of jobs completed, hours run or even the amount of products created by a die. It should also include tasks operators need to do daily to monitor the condition of your dies.

Your maintenance schedule should include the following:

Cleaning

One of the first steps in die maintenance should be removing any debris and dirt that has built up on the die, including the chambers where off-cuts and trimmings are stored. Cleaning your die is one of the most straightforward die maintenance measures to implement, and it has significant benefits for your die, including:

- Prevents friction that may slow down material moving between stations.

- Increases precision by stopping material from being displaced by debris while being cut.

- Reduces chamber clogging that can slow down production.

- Ensures operators can spot any problem areas or concerns easily.

- Keeps equipment sharp and in top condition.

Inspection

Another crucial part of die management is regular inspections of your die. Inspections help operators identify any equipment that needs to be replaced, equipment that needs sharpening or other concerns that may impact the functioning and output of your machine. These problems can then be dealt with and corrected before they become larger production problems later on.

Here are a few of the most important things to look for:

- Loose or missing fasteners, dowel pins and galled die sections

- Worn, blunt, chipped, cracked or dented parts that need sharpening, refinishing or replacement

- Adequate lubrication in high-friction areas, including die mating surfaces

- Broken or missing parts such as springs

- Wheels, dies and belts moving incorrectly

- Missing safety guards or cutting punches

Operating a die with blunt, worn, missing or loose parts can result in inconsistent cutting or folding, including frayed edges. Over time this can increase production costs as time and materials are wasted on substandard products that must be scrapped. Inspections are vital to spotting these errors before they become costly problems.

Sharpening

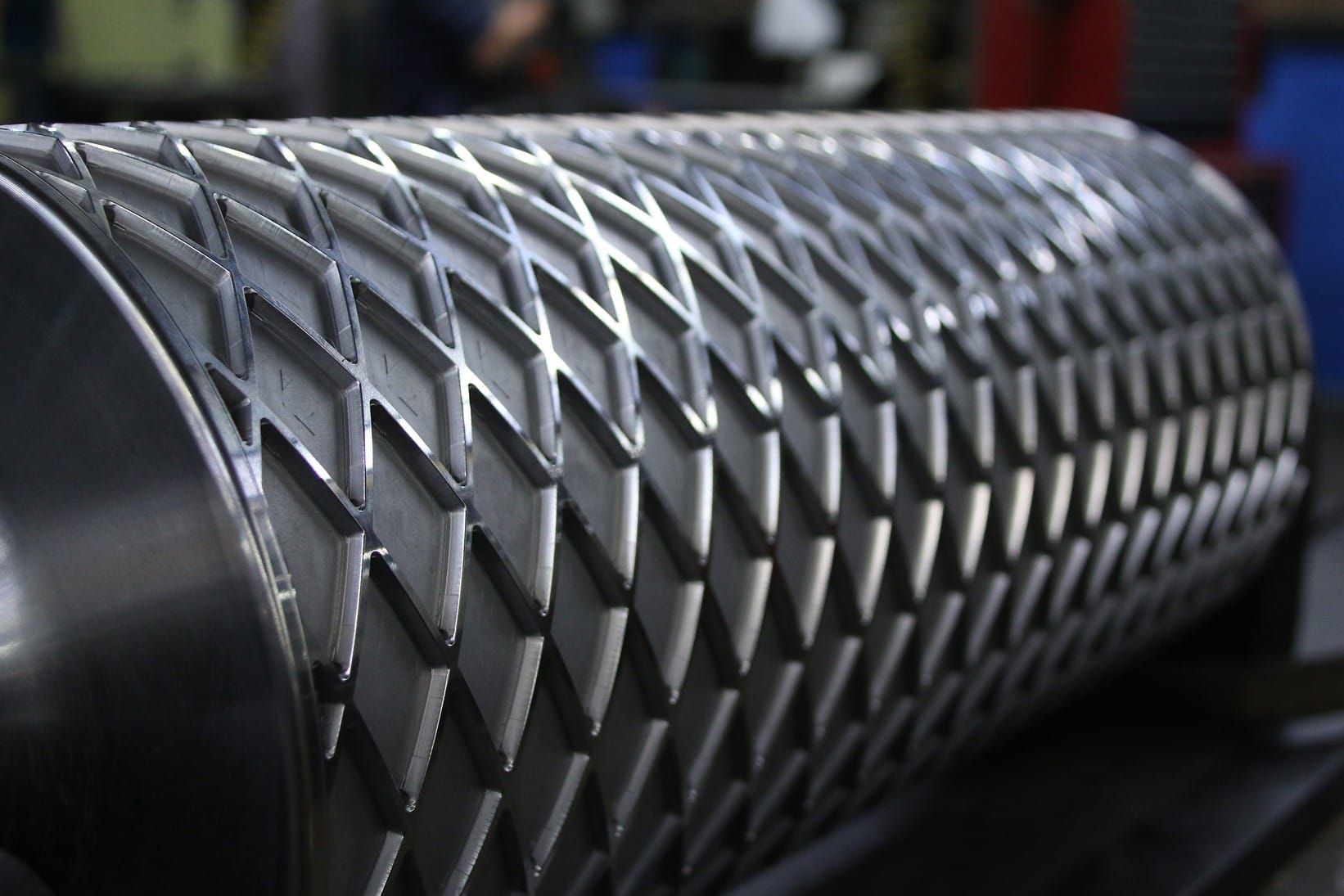

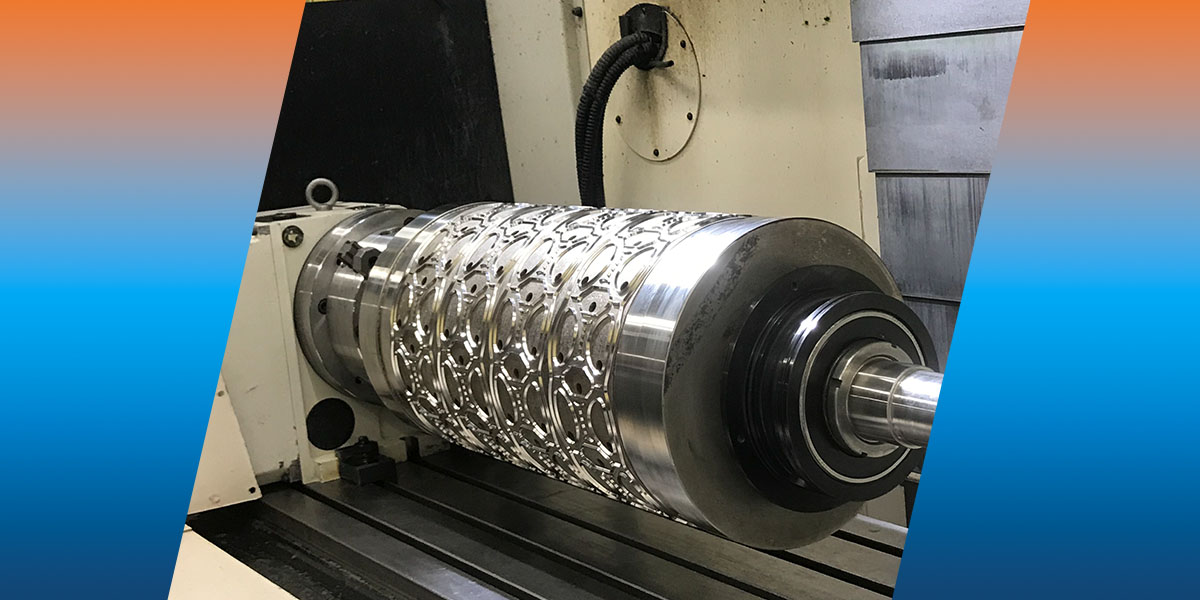

Dies wear down over time through everyday use. The cutting and punching sections are the most susceptible to this deterioration. The die parts that cut, slice or punch materials into shape must be sharpened regularly with a grinding wheel.

Blunt or dull dies can cause various issues, including substandard products, burrs, feeding problems and other safety issues that slow production and waste materials. Implementing a regular sharpening routine ensures you avoid these issues and improves the life span of a die.

When sharpening a die, it is vital that you use the right grinding wheel and cutting shear. Using the incorrect grinding wheel and method can result in excess heat building up in the die, causing it to soften and crack.

Shimming

Shims are added to dies to maintain the correct timing when cutting and punching materials. As with other die parts, shims wear down over time and must be replaced. Here are some things to keep in mind when shimming:

- Place shims properly: Crooked or overhanging shims can impact how dies perform.

- Keep shims clean: Debris and burrs can alter how the shims lie and affect the die’s timing.

- Ensure proper clearance: Shims should remain clear of slug drop holes, fasteners and dowels.

- Use the correct number of shims: Using too few or too many shims can impact the speed of the die.

Alignment and Recalibration

A die’s regular, repetitive movements can cause it to become misaligned over time. Misaligned dies can cause significant problems, especially when cutting precise products. A few microinches can result in drastic changes to your product. It is essential to monitor the alignment of dies and recalibrate them as needed to maintain high levels of precision.

Checking for Heat

Most die-cutting machines heat up when used due to the natural friction of all the parts and materials. However, too much heat may indicate an underlying issue with the device — either the hardware or the electrical system.

Take the time to monitor and record the peak temperatures of a die-cutting machine to identify any heat irregularities. Once the anomaly has been noted, you can correct it before it results in equipment failure or other safety issues.

Repairs and Replacements

The biggest part of die management is repairing and replacing broken, worn or missing parts. A well-defined die maintenance schedule can ensure repairs and replacements are done before the damaged or missing component evolves into a larger problem. A proper tool room management system also ensures you have the parts to limit downtime.

Choose High-Quality Dies and Parts From Best Cutting Die

With over 50 years of experience in the die-cutting industry, our team can engineer high-quality die-cutting machines and replacement parts that suit your operations. Our team works closely with you to engineer machines and components tailored to your unique needs. We can also help you train your technicians and create an efficient die maintenance program that saves considerable costs.

Talk to one of our specialists today to learn more!