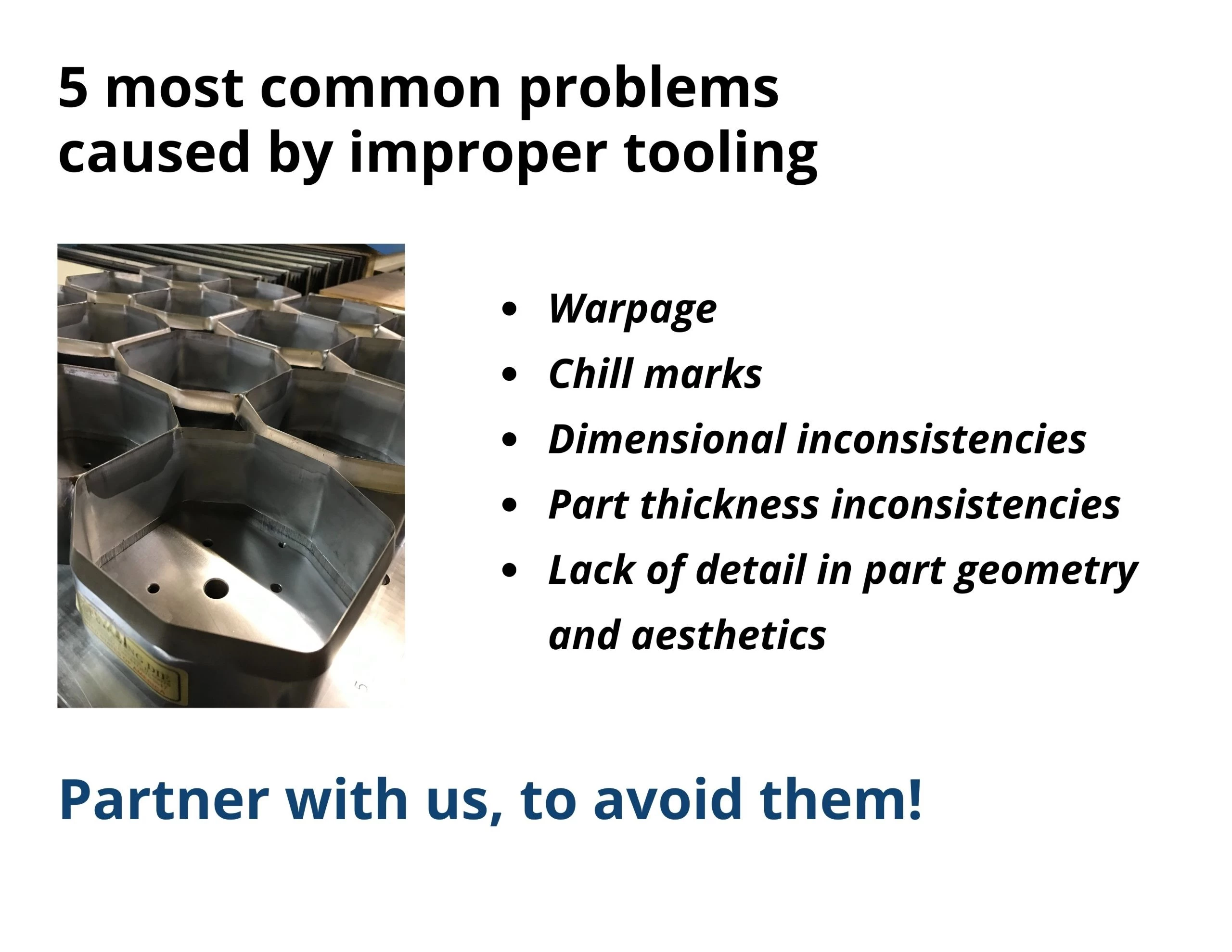

BEST Thermoforming Dies and Plates for Packaging

Manufacturing Capabilities for Thermoforming Applications

BEST manufactures hand-forged thermoforming dies to ensure high-quality products with long-lasting performance. We also use other manufacturing processes where applicable, including cutting dies using 5-Axis, water-Jet, torch cutting from a solid block of steel and Wire EDM.

Various steel thicknesses are available, including standard 1/4” and 3/8” upon request. Offering the BEST in thermoforming applications, we provide any die height required. In addition to cutting dies, BEST offers Mounting Plates, Baffle Plates, Cut Plates, and Base Plates for all GN and similar Thermoforming Machinery.

Thermoforming Applications Across Industries

- Food and beverage: Thermoforming dies are essential for creating various types of packaging solutions in the food and beverage industry, from containers to plastic trays. The cutting dies help to produce accurately cut and shaped packaging components, improving product protection and presentation.

- Medical: Thermoforming dies are used to cut and shape packaging for medical devices and pharmaceutical products. The precision cutting capabilities of these tools can help ensure that the final product meets medical packaging standards.

- Electronics: In the electronics industry, thermoforming dies facilitate the precise cutting of electronic component packaging. These tools can help curb material waste, streamline production and enhance finished product quality.

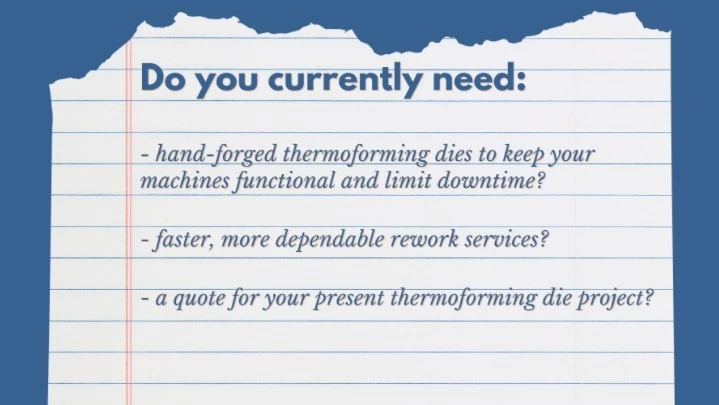

Thermoforming Dies Retooling Services

If you need to retool your thermoforming dies, our team is here to help. We provide comprehensive cutting die resharpening, retooling and repair services, including:

- Major and minor welding repairs

- New shim plates (0.010″ to 0.750″) installation

- Mold shim plate replacements

Our unique process allows for longer die life and an easier sharpening process, eliminating the need for multiple shims and extensive grinding. We grind the cutting edge to the minimum required, or similarly grind the mold plates accordingly.

CNC Advantage for Thermoforming Applications

We finish all thermoforming cutting dies using computer numerical control (CNC) machinery, which operates based on pre-programmed software that dictates the movement of the tooling. With our CNC capability, we can create custom-drilled mounting hole patterns on the dies to make them uniform and interchangeable on the mounting plate.

Superior Steel Quality

Using pre-hardened steel thermoforming dies yields higher-quality, more precise cuts for improved productivity and profitability. What’s more, these tools can endure high-volume production for longer periods than average steel. We use steel that is much harder and tougher than other suppliers, lasting on average twice as long before sharpening is required. Chip outs found in the crotch area are also reduced when BEST’s superior quality steel is used.

Thermoforming Machine Salt Bath & Tempering Depth

As part of our hand-forging manufacturing process, all our thermoforming dies are tempered in a salt bath for thorough sharpening in order to achieve consistent hardness for the cutting edges. The tempering depth for the hand-forged dies is 20 to 25mm, which is around ⅓ of the total height. The depth we use is double that of other suppliers, making the hardness of our thermoforming die more uniform.

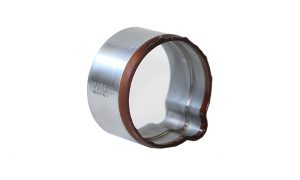

Thermoforming Die Chrome Plating & Finishing Applications

At Best Cutting Die, we chrome plate thermoforming dies for added protection from wear and corrosion. The chrome-plating process also provides many other benefits, such as increased hardness and improved lubricity to make ejectors run smoothly. In addition, all our thermoforming dies are wax-dipped to protect cutting edges during handling, transportation and storage.

Find Quality Thermoforming Dies at Best Cutting Die

With Best Cutting Die, thermoforming die cutting has never been easier. We’re thermoforming and blister die manufacturers with over 50 years of experience, and our team is committed to providing industry-leading die cutting solutions. Our engineers work closely with you to develop the ideal design and craft a high-performing, reliable tool that supports your thermoforming applications.

Contact us online to learn more about our selection or call (847) 649-6549 for personalized advice and recommendations.

From Start To Finish, BEST Offers Incredible Thermoforming Application Options.

Contact Our Team Today!

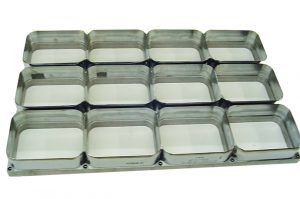

Mold plate, New Die Sets, Thermoforming

Retrofit, Existing Die Sets, Thermoforming