High-Quality AMC Dies for Envelope Converting

For the finest in AMC craftsmanship, send your dies to Best Cutting Die. Whether you need a new envelope die, die sharpening or a complete rebuild, Best Cutting Die has you covered. Our knowledgeable technicians have extensive experience working with AMC dies and die-cutting components, so you can count on us to deliver quality service and restore the functionality of your tools.

AMC Die-Cutting Solutions

Best Cutting Die has an F.L. Smithe AMC envelope die-cutting machine that is fully operational for testing. We thoroughly test every envelope cutting die before it leaves our facility, whether new, resharpened or rebuilt. This level of dedication ensures that you receive a BEST quality die.

We’ve offered AMC envelope die-cutting services for over 30 years, initially developing this department by working with the original machine manufacturer (OEM). Our envelope die-cutting services follow all FL Smithe standards for replacement parts, procedures and safety to ensure long-lasting results.

Best Cutting Die – the safest hands to entrust your dies!

Layout Design Services

Our Product Manager and CAD designer will work together to determine the BEST possible layout for your new die. Our die-cutting tools offer you nice-looking envelopes while minimizing paper usage. Our experience makes a difference.

AMC Envelope Die-Cutting Service Advantages

- Enhanced efficiency: Our die-cutting services help to optimize the performance of AMC dies for efficient operation. With proper maintenance, the tool experiences fewer breakdowns, leading to greater productivity and reduced downtime.

- Improved product quality: The services we provide keep envelope-converting AMC dies in good working condition to prevent defects in the cutting process. As a result, the tool continues to produces precision-cut products that meet quality standards.

- Longevity: Regular servicing and maintenance by our expert team can help preserve the integrity of AMC dies, which can prolong the lifespan of tools and reduce the need for frequent replacements.

- Cost savings: With our maintenance services, we can identify and address potential issues before they escalate into costly repairs or replacements. Routine upkeep can help you avoid breakdowns, emergency repairs and production losses.

- Increased safety: Our AMC die-cutting services help to ensure the tools meet safety standards and regulatory requirements while creating an overall safe working environment for your team.

Train With the BEST

Whether your AMC operator is new or experienced but wants to learn more, our AMC die training program has definite value. While we service and machine your AMC envelope die, you may also want to consider sending in one of your employees for our one-day training program.

If you are already sending us an AMC envelope die to be serviced, the training itself is free! Your only cost is in transporting the trainee to and from our facilities.

Best Cutting Die recommends that your trainees spend approximately one full day at our facility. This will allow enough time for hands-on training, as well as questions and reviews.

Learn more about what Best Cutting Die’s training program has to offer by checking out our training outline below:

- Basic Die Construction and How Construction Relates To:

– Maintenance

– Adjustment

– Troubleshooting AMC Envelope Dies - The Importance of Lubrication

– Setting the Pressure and Timing

– Types of Lubes - How To Tell When You Need a Paper Adjustment or Peening

- Peening the Die

– About Tools

– About Peening (what actually happens when you peen the die) - General Housekeeping Needs and Their Importance

Why Choose Best Cutting Die?

Contact Us for Expert AMC Die-Cutting Services

Book your training visit

with your dedicated technical consultant HERE.

Test Cutting an AMC Die

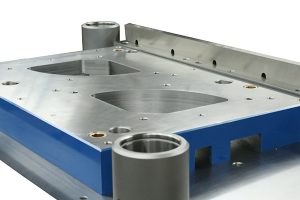

- Female plate mounted on the base plate

- Magazine rack with to 2-book ends

- Base plate with cut-off knife

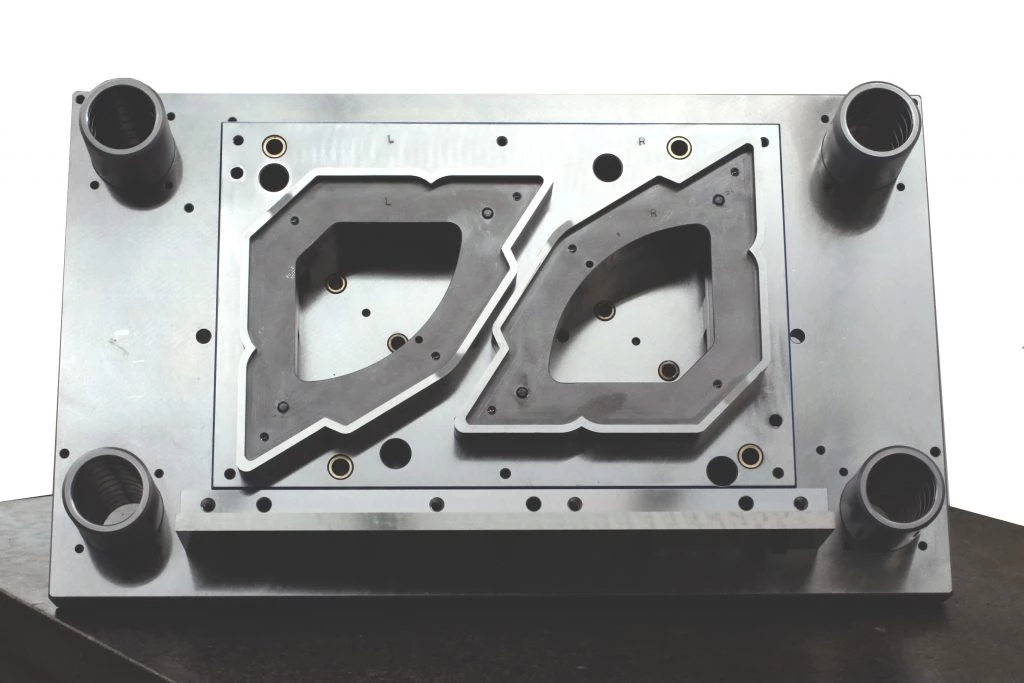

- Top plate with female punches

- Front view - Top plate with female punches

- Complete AMC Die Assembly

- Complete AMC Die Assembly