BEST Cutting Die In-House Process for Die Cutting Solutions

BEST Cutting Die offers complete metal working services featuring all in-house capabilities, including vacuum heat treating, computer controlled machining centers and state-of-the-art testing/inspection equipment. All in-house process control provides optimal quality control, service and quick turnaround times.

At Best Cutting Die, we’re committed to going above and beyond our customers’ expectations by providing them with exceptional products and services. By completing our processes in-house, we get complete control over the quality of our manufactured products, after-sale services and delivery schedules. When you work with our team of engineers and technicians, you can be confident that you’ll get the best die cutting solutions and customer support every time.

Special Machining

BEST stays one step ahead of the demands of the industry by continually upgrading and adding equipment, services and personnel. Skilled craftsmen operate over 40 pieces of CNC equipment and over 100 machines overall, completing the precision machine and hand work necessary to guarantee unexcelled quality and fast, responsible service.

- CNC Turning & Grinding

- Full Turning & Grinding Capabilities

- Up to 26” Diameter & 120” Length

- CNC Milling, Horizontal & Vertical

- Positioning Accuracy Guaranteed

- Prompt response for emergency, prototype and special situations

- Over 40 CNC Machining Stations

- Wire & Conventional EDM

- Large Capacity Capabilities

Positioning Accuracy: .00005” over Full Stroke - Large Length and Diameter Rotary Capability

Hand Forging

As an experienced leader servicing the Converting Industries for 50 years, BEST offers Hand-Forged, Steel Cutting Dies. Anything that can be made of metal can generally be made stronger and more weight-conscious by forged steel.

Our forged envelope, label and direct mail dies are stronger and longer-lasting than average steel dies, making them ideal for high-volume production. What’s more, these heat-treated dies maintain a sharp edge so you can enjoy precise cuts on the most complex designs.

Superior Hand-Forged Steel Quality Equals Better Performance

The hand forging process ensures a higher-quality product that performs better and for longer. Our hand-forged steel products are:

- Through-hardened up to 56 Rockwell

- Designed for high-volume cutting in demanding applications

Reliability & Uniformity

Speed up your manufacturing process while creating products that maintain your high quality standards. Other benefits include:

- High degree of reliability and tolerance capabilities

- Offer uniformity of composition and structure

- Forged steel dies have minimum variation in machining and mechanical properties

- BEST hand-forged dies are stronger due to the fact that the grain flow of the steel is altered, conforming to the part’s shape.

- The hand-forging process makes it possible to cut more difficult designs that accommodate high loads and stresses.

- Forgings are free from internal gas pockets, voids or cooling defects that can cause unexpected fatigue or impact load failure.

Less Susceptible To Breakage

More durable dies and cutting machines allow you to save time and money on repairs.

- Forged steel tends to be more flexible than wrought steel in the final product, regardless of the blend

- Steel, especially when heated to forging temperature, is ductile and malleable; able to be shaped by applying pressure.

- The Hand-Forging process allows a billet of steel to be shaped permanently without cracking, due to its plasticity.

- BEST Forged Steel Cutting Dies do not chip out like those made using other processes or hand forging with inferior steel.

Salt Bath & Tempering Depth (VIDEO)

All Forged Cutting Dies are tempered in our in-house Salt Bath to a depth of 20-25mm (approximately 1/3 of total height). Added depth allows BEST Dies to be sharpened approximately twice as many times as Dies made by other suppliers, and the salt quenching causes less distortion and produces more uniform and consistent hardness.

The Salt Bath heat treating process allows us to achieve a consistent hardness on the cutting edge of the hand-forged die, while allowing our customers to easily work with the back-half of the die when needed. Due to the fact that salt can attain very high temperatures (> 700° C), and because it displays remarkably uniform heat-transfer characteristics, molten salt heat treatment is considered to be the best choice in hardening hand-forged cutting dies.

Salt Bath, Heat Treatment

- Heat treatment, hand-forged dies

- Heat treatment, hand-forged die

- Heat treatment, hand-forged die

TESTIMONIALS

In-House Heat Treatment

The advantage of having all in-house heat treating and forging capabilities allows BEST complete quality control over our products and services. Most other manufacturers have to depend on outside sources, which not only affects quality, but delivery schedules as well. BEST offers the following in-house Heat Treating processes to provide the highest level of quality and service possible.

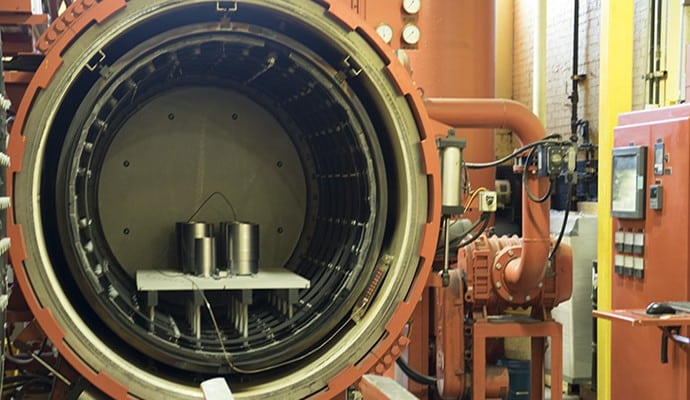

In-house Vacuum Furnace (VIDEO)

The capability of having all in-house inspection, testing and vacuum heat-treating equipment enables BEST to have complete quality control of the parts we manufacture. With expansion and the advent of larger diameter roll work in the rotary die industry, BEST now offers:

- Heat-Treating Capability For Virtually All Materials And Sizes

- Uniform Hardness

- Minimum Part Distortion

- Larger Capacity Vacuum Heat-Treating Equipment

- Furnace

- Furnace

- Furnace

Cryogenic Chilling Chambers (VIDEO)

In addition to vacuum heat treating, new state-of-the-art cryogenic chilling chambers have been installed with the capability of sub-zero treatment to -300° F. This procedure follows heat treating and is used to stabilize the material to increase the life of the dies.

Induction Hardening

Induction hardening is a heat-treatment process that enhances the mechanical properties in a specific area of the steel component. The resultant hardened area improves the wear and fatigue resistances along with strength characteristics. These properties are desirable for shaft journals and other parts that experience torsional loading and surfaces that experience impact forces. Induction processing is performed one part at a time allowing for very predictable dimensional movement from part to part.

In-House Quality Control

BEST performs all inspections, testing and quality control procedures using equipment available on-site. Outside sources are not relied upon, providing complete control over the quality and delivery times of our products and services.

The following quality control procedures are in place to assure that all parts are manufactured to the required specifications and perform as required:

- State-of-the-art programming software

- Hard copy output available for customer inspection

- Optimal magnification up to 120x and microscopic inspection, guaranteeing precise edge quality

- Skilled technicians utilize computer controlled and manual gauge equipment to test all products for hardness and concentricity, as well as edge quality

- Dies are tested duplicating actual production situations whenever possible

- Vacuum heat treating and cryogenic sub-zero treatment are also completed in-house

Get the Highest-Quality Dies From Best Cutting Die

Find the forged label, envelope or other steel dies you need when you partner with BEST. With over 50 years of experience creating dies for countless applications, we know how to engineer products you can count on. Our in-house process allows us to oversee every aspect of production, from designing and manufacturing to reengineering and retooling.

We use innovative technology and our expert knowledge to create die cutting equipment that can improve your operational efficiency and increase profitability. Find out more about our selection of products and services by filling out our contact form or calling us at 847-675-5522.