How to Choose a Die Supplier

Choosing a Die Supplier

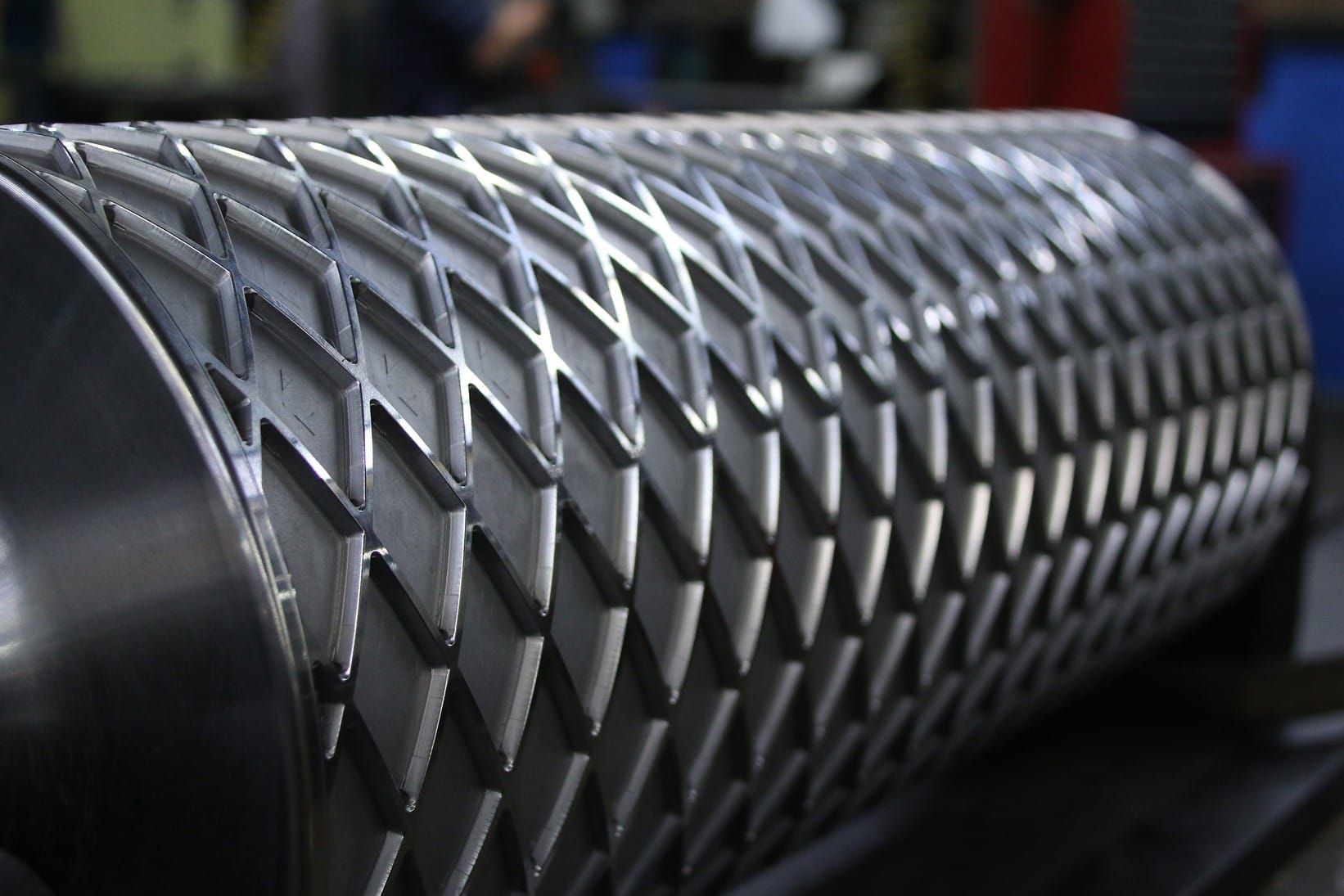

The unique process of die cutting cuts various materials into shapes using a predetermined pattern and a die, a sharp-edged tool used for piercing and shaping materials. This tedious process is used for metal sheets, fiberglass, wood, paper, plastic, fabric, and rubber.

When choosing a die supplier, it’s crucial to think about many variables, so you can make the right decision for your company. Here are six sourcing strategies to keep in mind when learning how to choose a die manufacturer.

1. Check In-House Processes and Capabilities

The die cutting process can effectively mass produce components for industries like automotive, packaging and consumer goods. However, it can also support smaller jobs with fewer needed parts. While the main purpose of a die-cutting machine is to cut various materials, it has other capabilities, such as scoring, forming and perforating.

As you’re searching for a die-cutting supplier, check to see if they have in-house processes and capabilities. If a supplier has in-house capabilities, it means they can deliver incredible quality control, turnaround times, and one-on-one complete assistance. Here are some in-house qualities to consider:

- Do they deliver complete metalworking services?

- What’s their process of overseeing each aspect of production?

- Do they have limited capabilities?

- Can they meet your specific requirements?

- Do they adhere to industry standards and regulations?

In some cases, working with a die supplier with a specialization can be helpful if you’re in a niche field where they’d have high knowledge of your industry. However, you could also be looking for a supplier with a multitude of skills. Take time to understand a supplier’s services, experience levels and whether they can deliver customizations.

For suppliers with complete in-house processes, they can be your one-stop shop, delivering services like design, tooling, molding, assembly, packaging and manufacturing. Anything that’s not done in-house will take more time and money to coordinate.

2. Look Into Their Commitment to Customer Service

Any company, not just within the die cutting sector, who puts value into customer service is a key factor you want to consider.

- Do they offer after-sales support like maintenance?

- What’s their reputation with others in the industry?

- Do they offer any type of training, best practices or expert advice?

If a die supplier works to continuously improve their processes, technology and services, it’s a high indication they put their customers first. Communication is a crucial component in customer service, so make sure your supplier updates you with touchpoints throughout the entire process. A representative should take you through the plan, provide instructions and be clear about the supplier’s initiatives, even when disruptions occur.

To help you gain a better understanding of a manufacturer’s commitment to customer service, schedule an on-site visit. This will help you see the process and their level of accommodation. It also allows you to view them at a full professional scope.

3. See if In-House Engineering and Design Services Are Available

You can gain additional benefits from the partnership with in-house engineering and design services integrated into a die supplier’s operations. Consider the following:

- Is design part of the process?

- Do they inspect their equipment and end products?

- What types of in-house engineering and design technology do they have?

- Do they have trained technicians with a diverse set of capabilities?

- Can they work with multiple materials?

Researching a die supplier’s engineering and design services allows you to understand whether they can keep up with your demand. What’s their scalability? Do they have the capacity to increase the scale of their production if needed?

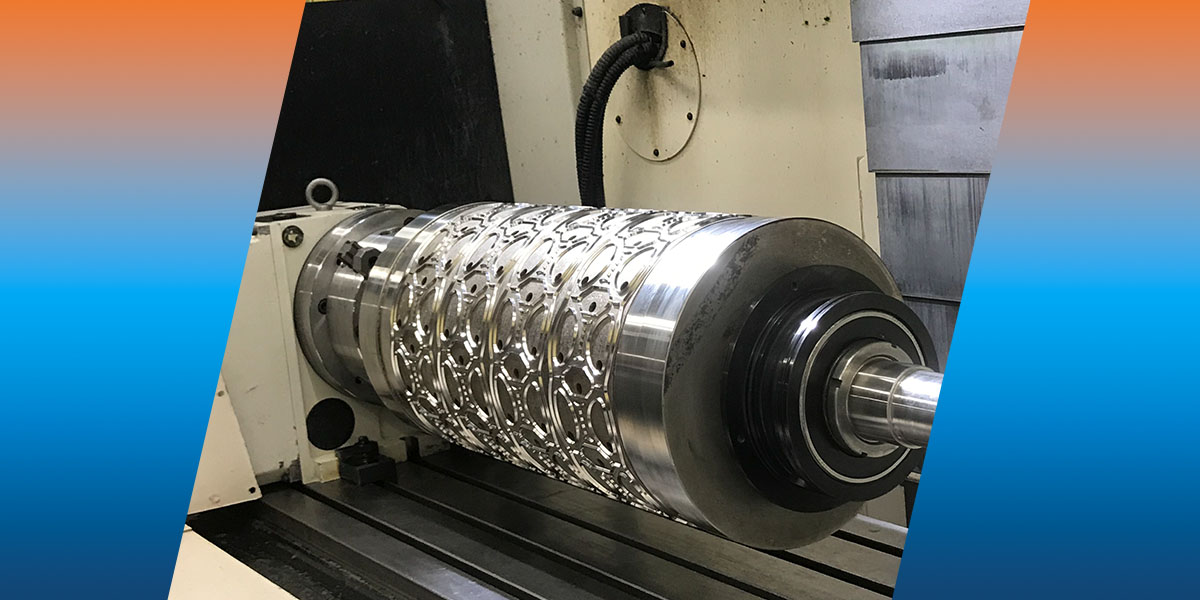

Many companies work with computer-aided design (CAD) technology that can connect to the computer numerical control (CNC) machine. Check to see if their technology operates through an automatic or semi-automatic process. With different machines and technology, a supplier’s technicians should be well-versed in all of them, including any solutions that require hands-on expertise.

4. Note How They Deal With Technical Diagnosis and Technical Assistance

When working with any type of machinery, malfunctions are sure to arise. If you experience issues with your die cutter, will the supplier troubleshoot the issue on-site? It’s crucial to partner with a manufacturer to help maintain your die cutter and keep your operations running efficiently.

For example, Best Cutting Die will diagnose the problem, whether it’s technical or mechanical, and then determine a solution that best fits your situation. Throughout the process, we pride ourselves on exceptional communication to ensure you’re in the loop and understand our solutions.

5. Understand Their After-Sales Services

These services encompass any type of support you receive after making the final investment. With some companies, it’s a one-and-done deal where you never hear from them again. Look for a die supplier controlling their after-sales services and in-house shipping solutions. For example, ask a potential supplier about their instant tracking and on-time delivery track record.

After-sales support can range from answering simple questions and giving expert advice to providing tracking and even training and assistance. When you partner with a die supplier, it should be a true partnership where your success is their success. A die manufacturer should work with you to understand your timeline, budget, shipping and other areas in which you may need support.

6. Check for a Comprehensive Training and Maintenance Program

A training and maintenance program is part of the after-sales customer service you’d be searching for. Consider the following components:

- Does the supplier offer any type of training online or on-site?

- What type of maintenance assistance do they have?

- Are they able to support new businesses with limited knowledge?

These insights will help you learn how your die cutter ultimately works to increase productivity and efficiency. If they offer field training to assist you with a die-cutting solution, it’ll help you gain insight into the entire usage of a machine and help you take control of your operations.

Why Choose Best Cutting Die as Your Supplier

Here at Best Cutting Die, we deliver complete metal working services with in-house capabilities on every level so we can oversee each aspect of production. For example, we’re in charge of designing, manufacturing and reengineering, retooling, shipping and customer service.

Best Cutting Die conducts all testing, inspections and quality control procedures instead of relying on outside parties. This gives us complete control over the quality we deliver and the timeliness of our services. Further, we work to continuously improve our technology, processes and services to help you save money, produce less scrap and achieve quicker setup times.

We have knowledgeable representatives who offer on-site and online training to help you learn more. Our comprehensive training and maintenance program helps improve your production lines’ productivity and capacity while giving you more insight into how things work, resulting in cost-saving advantages.

Contact Best Cutting Die Today

Through expert knowledge, our engineers and technicians offer the best cutting solutions and top-notch customer service to help improve the efficiency of your operations. Are you ready to partner with us for your next project? Contact us today!