In-House Retooling, Tempering & Plating for Thermoforming Applications

From Precision Grinding/Sharpening to Chrome Plating – Complete Thermoforming Tool Solutions.

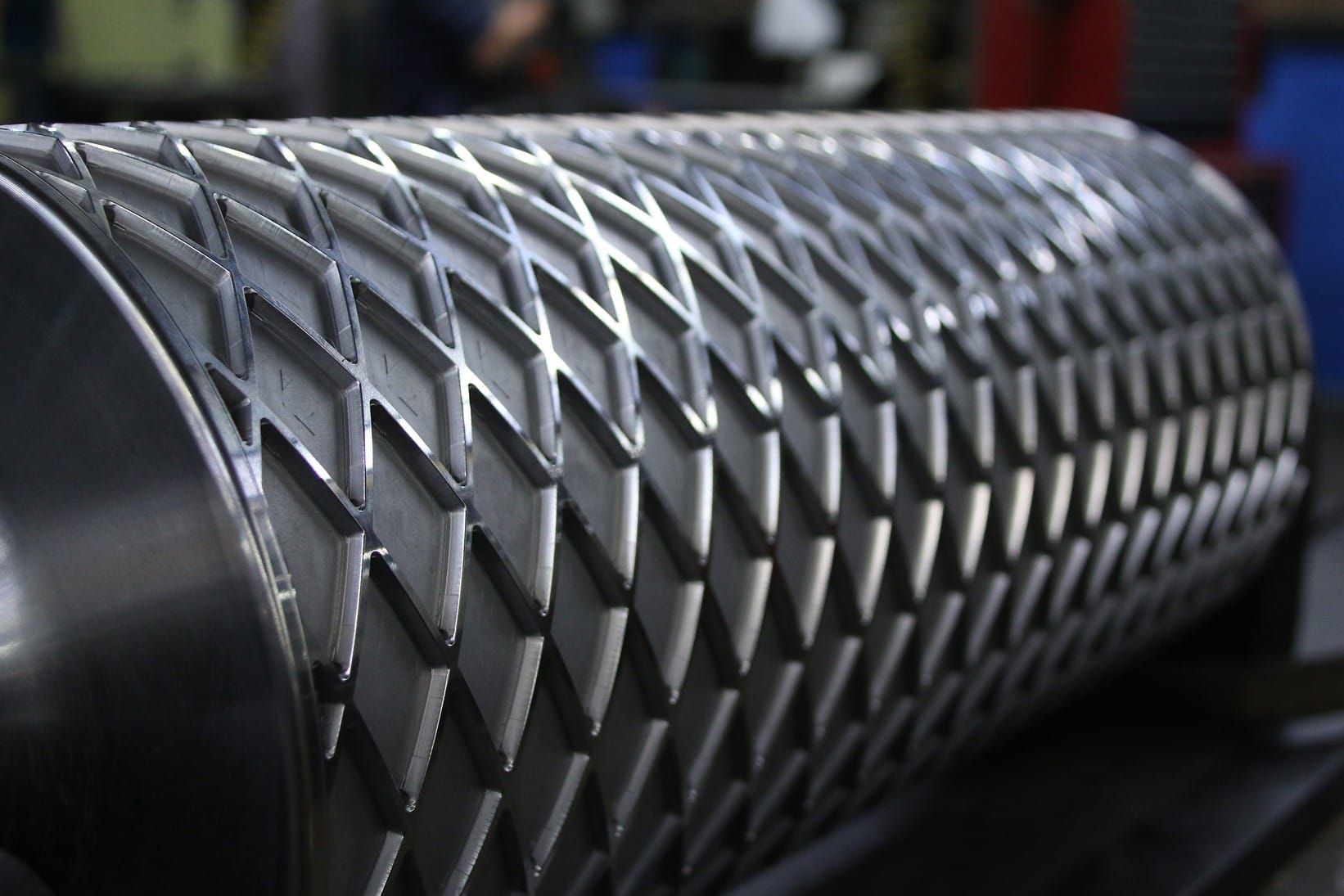

BEST is your single-source American manufacturer of premium hand-forged thermoforming dies.

We offer superior tooling solutions in a range of steel thicknesses (including standard 1/4”and 3/8”) in any die height required. We manufacture our dies from quality steel that is substantially more durable than most conventional suppliers, lasting on average twice as long before resharpening is required.

Efficient Retooling Services for Your Thermoforming Equipment

BEST provides complete grinding and sharpening/retool services for cutting dies, including:

- Major and minor welding repairs.

- Installation of new shim plates (0.010” to 0.750″).

- Replacement mold shim plates.

CNC-Based Precision for Thermoforming Applications

All new thermoforming cutting dies are finished in our precision CNC machine shop. Our CNC machining services include custom-drilled mounting hole patterns on the backs of dies, making each die identical and interchangeable on the mounting plate.

Learn More About Our State-of-the-Art CNC Machine Shop →

Salt Bath and Added Tempering Depth

All BEST hand-forged, thermoforming cutting dies are tempered in our in-house salt bath to a depth of 20-25mm (approximately 1/3 of total height), while the competition only tempers their forged cutting dies to a depth of typically 8-10mm. This added depth allows BEST thermoforming dies to be sharpened approximately twice as many times as dies made by other suppliers.

Added Value Die Chrome Plating and Precision Metal Finishing

Every new cutting die made by BEST is chrome-plated to 3/8” from the finished cutting edge as part of our all in-house standard process. We also chrome-plate retooled dies upon request at no additional charge. Our custom chrome-plating process increases the tool’s hardness while adding corrosion resistance and improved lubricity, making the ejectors work more efficiently. Finally, every die is also wax-dipped for cutting-edge protection during handling, shipment, transportation, and storage.

From Start to Finish, BEST Offers Incredible Thermoforming Application Options.